Kelsons Engineers And Fabricators

E - 22 / 23 / 26, M. I. D. C. Shiroli, Kolhapur - 416 122, Maharashtra, India.

Tel. No. : +91 - 230 - 2460543, 2460 161

Fax. : +91 - 230 - 2460543

Contact Person : Mr. Ravikumar ( MD )

Mobile : +91 - 98221 12162

Mail Id: response@kelsonsgroup.com

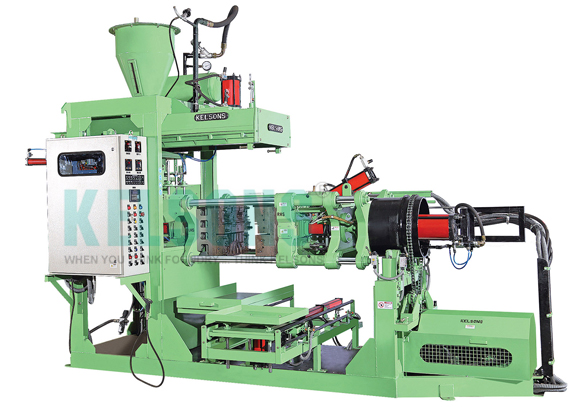

KELSONS can provide standard models and tailor made core solution to your specific needs using experience

gained from large & varied installed base. KELSONS have developed compact machine with multiple parting

lines for medium & small jobbing foundries.

PRIME FEATURES ARE

Cold Box Core Shooters - Vertical Parting

Capacities

MODEL - Pneumatic / Hudraulic

SALIENT FEATURES

Universal Model

Horizontal Parting

Two Station Horizontal Parting

Cold Box Core Shooter - 100 kg

Fully Automatic Cold Box Core Shooter -

Vertical Parting - 30 kg

Fully Automatic Cold Box Core Shooter -

Horizontal Parting - 100 kg

| Technical Data | |||||||||

| Model | KCBCS - 3 | KCBCS-FA-7 | KCBCS-FA-10 | KCBCS-FA-15 | KCBCS-FA-20 | KCBCS-FA-30 | KCBCS-FA-50 | KCBCS-FA-80 | KCBCS-FA-100 |

| Type | Vertical / Horizontal Particle (UniversalSystem) | ||||||||

| Shoot Capacity | 3 kg | 7 kg | 10 kg | 15 kg | 20 kg | 30 kg | 50 kg | 80 kg | 100 kg |

| Core Retrieval - Type | Manually / Automatic | ||||||||

| CONTROL SYSTEM | |||||||||

| Operation Type | Automatic / Pneumatic | ||||||||

| Cycle Control Type | Automatic by means of PLC with MMI | ||||||||

| Machine Operation | Pneumatic / Hydraulic | ||||||||

| Machine Dry Cycle Time | Dependes On Machine Capacity | ||||||||

| Electricity / Power Required to Equipment | Volts 415 / Ph 3/Hz 50 / Kw 4 | ||||||||

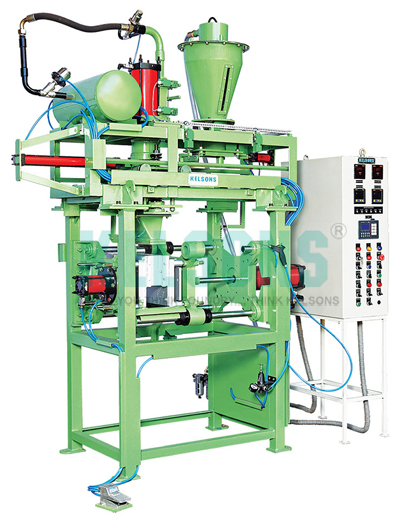

Core Paiting Unit - Bath Type

Core Paiting Unit - Bath Type

Core Dipping Unit

Specification : Unit is designed to process the paint to sand Cores. Unit can be placed on regular floor having unit structure. This unit provides uniform paint to cores due to provided system of paint shower system

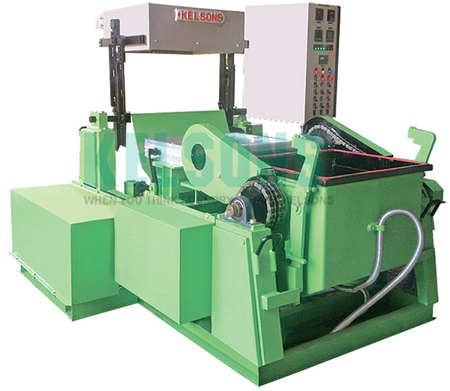

Core Sand Mixer

Kelsons make Core Sand Mixer are heavily constructed With suitable Motor and gearbox, For long and

durable life all Mixers are provided with Stainless Steel Sheet Lining inside main shell, Scraper are

brazed with Carbide Tips at Bottom & Side

Note: For Chemical Bounded Sand this mixer is efficiency is limited to 75-80 % of the full load capacity Auto Dozing is also available Batch Capacity 150, 250, 300, 350, 500Kgs. & 1 Ton

Cold Box Core

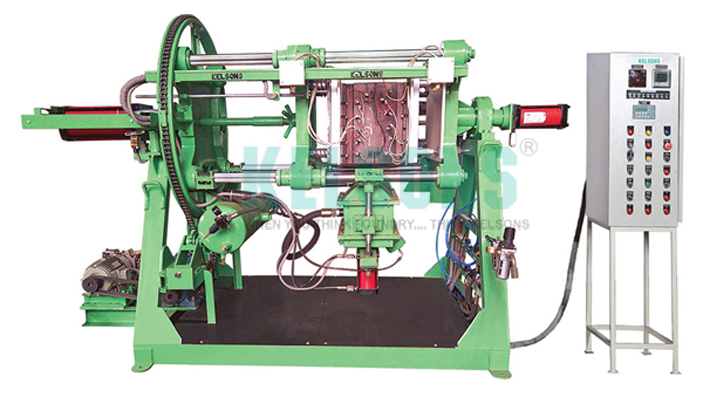

Shell Core Shooter Machine

KELSONS can provide standard models and tailor made core solution to your specific needs using experience gained from large & varied installed base. KELSONS have developed compact machine with multiple parting lines for medium & small jobbing foundries.

PRIME FEATURES ARE

Vertical Parting - Top & Bottom Shooting - Rollover - Swing Door

| Vertical Parting - Top & Bottom Shooting - Rollover - Swing Door/ | KCS-FA-VP-TSBS-RO-SD-450x450 |

KCS-FA-VP-TSBS-RO-SD-550x550

|

| KCS-FA-VP-TSBS-RO-SD-650x650 |

TYPES OF SHELL CORE SHOOTER

Fully Automatic Machines

Shell Core Shooter Vertical Parting Top Shooting Fully Automatic

| Shell Core Shooter - Vertical Parting Top Shooting | KSC-FA- VP- 300x600 | KSC- FA-VP- 400x400 |

| KSC- FA-VP- 400x600 | KSC-FA- VP- 500X600 |

SALIENT FEATURES

Vertical Parting Top Shooting

Horizontal Parting Top Shooting

Rollover Vertical Parting Shooting Machines

Shell Shooting Head With Core Oven

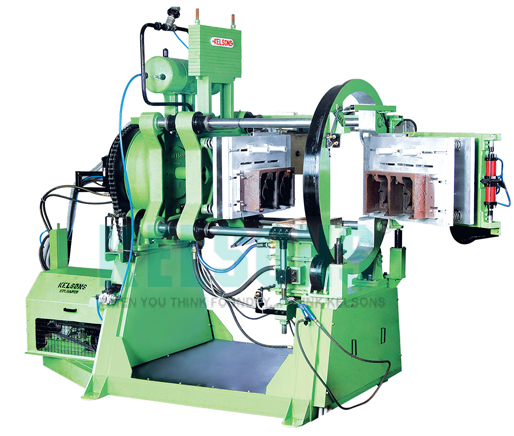

Shell Moulding Machine And Shell Fuser

KELSONS can provide standard models and tailor made core solution to your specific needs using

experience gained from large & varied installed base. KELSONS have developed compact Single Station and

Four Mould Machine with Semi and Fully Automatic for medium & small foundries.

PRIME FEATURES

• Proven sturdy and job rated equipment

• Heavy-duty plates and sections

• Spring type-clamping system

• Built in control system to facilitate various operations.

Model- We are having different type of Shell Moulding Machines – Single Station and For four Mould

machine Semi and Fully Automatic.

Rollover Vertical Parting Swing Door

| Technical Data | ||||

| Model | Heater Plate Sizes | |||

| Vertical Parting TopShooting | KCS-FA-VP-300x600 | KCS-FA-VP-400x400 | KCS-FA-VP-400x600 | KCS-FA-VP-500x600 |

| Horizontal Parting Top Shooting | KCS-FA-HP-400x400 | KCS-FA-HP-400x600 | KCS-FA-HP-500x600 | KCS-FA-HP-600x600 |

| Rollover Vertical Parting Shooting | KCS-FA-RO-VP-300x400 | KCS-FA-RO-VP-400x600 | KCS-FA-RO-VP-600x600 | KCS-FA-RO-VP-500x700 |

| Rollover - Vertical Parting - Swing Door | KCS-FA-RO-VP-SD-500x700 | KCS-FA-RO-VP-SD-600x900 | ||

| Vertical Parting -Top & Bottom Shooting -Rollover - Swing Door | KCS-FA-VP-TSBS-RO-SD-450x450 | KCS-FA-VP-TSBS-RO-SD-550x550 | KCS-FA-VP-TSBS-RO-SD-600x600 | |

Shell Moulding Machine – Fully Automatic

| Shell Moulding Machine |

KSM-FA- 16”x16’’ |

KSM- FA-20”X20” |

|

KSM- FA-20”X22” |

KSM- FA-20”X24” |

Shell Moulding Machine - Semi Automatic

| Shell Moulding Machine | KSM-SA- 16”x16’’ | KSM- SA-20”X20” |

| KSM- SA-20”X22” | KSM- SA-20”X24” |

Resin Coating Plant

This Shell Sand coating unit is used for warm process for preparing free flowing resin

coated sand. It is designed to meet any shell moulding requirements. The entire resin coating process is

fully automatic and precisely controlled. Control panel of machine is provided with individual timer for

each operation which can be easily adjusted to accommodate various types of resins and sands. Hot air is

blower through the sand mass for solvent evaporation. Skip Hoist is of special design with low loading

height for fast easy loading. Resin and hexa is manually charged into the mixer. Double – Deck vibratory

screen prevents reagglomeration and breaks down any lump formation. Lower Screen thoroughly separates sand

into individual grains providing maximum mass density. Cooling conveying and collecting unit further cools

the resin coated shell sand removes residual solvent which passes through cyclone.

UNIT CONSIST OF

Model - We are having different Capacity of Resin Coating Mixer – 75 Kg, 150 Kg and 300 Kg.

Shell Fuser

Shell Moulding

Models

KSM-FA-16x16, KSM-FA-20x20

KSM-FA-20x22, KSM-FA-20x24

Sand Dryer

KELSONS can provide standard models Sand Drier for removing the Moisture of incoming

silica sand. We are using imported make burner to control the noise, back pressure, less carbon

deposition, Sand Drier include Sand feeding hopper, Rotary drum, Burner, Hose connections and Drive

assembly, bottom frame with inbuilt self sand uniform loading System. SAND DRIER

ADVANTAGES OF BURNER

Note : To get good efficiency of Drier wet Sand loading should be Uniform Model : We are having different Capacity of SAND DRIER – 500KG, 1T, 2T, 3T, 5T AND 10T

| SAND DRYER | KSD - 500 | KSD – 1000 |

| KSD - 2000 | KSD - 3000 | |

| KSD-5000 | KSD-10000 |

Core Oven

Construction : Casing With Insulation Provided To Minimize Heat Losses. Doors Are

Double Walled Insulated To Avoid Heat Leakage’s Air-Cirutlaion Heating Will Be Inter Locked With Fan,

Control Panel, Safety Devices For Door

Sizes Available

Sand Sievers

Portable Sand Siever